E-PTFE nanomembrane compost fabric PTFE organic compost fabric

Process introduction

The e-PTFE membrane covered aerobic composting system consists of:

①e-PTFE aerobic compost membrane

②Control system

③Aeration system

④Temperature control system

⑤Film sealing parts

Process characteristics

·Environmentally friendly, no odor, no bacteria required for fermentation.

·Simple operation, intelligent and unattended.

·Low energy consumption, using low pressure and intermittent fan operation.

·”Zero” failure, no maintenance required, simple system.

|

brand |

YINGJIE |

Custom processing |

yes |

available for sale |

Nationwide |

|

Be applicable |

Chicken, duck, horse, cow, sheep, pig |

Dimensions |

custom made |

Purpose |

fermentation |

|

Package |

custom made |

product specifications |

custom made |

type |

volume |

The organic compost fabric uses the special microporous structure of the ePTFE membrane to provide a controllable pressurized and breathable closed environment for solid waste treatment and organic compost in the pile trough, which does not allow bacteria and odors to pass through, but also keeps the pile It can reduce the required humidity of objects, be waterproof and windproof, speed up the degradation time of piles, and improve the environmental sanitation around piles.

As a new treatment method, nanomembrane compost has several advantages such as low fermentation investment cost, good fermentation effect, and good fermentation environment compared with traditional composting methods. Composting refers to a biochemical process that uses microorganisms widely found in nature to controlly promote the conversion of degradable organic matter in solid waste into stable humus. Composting uses various organic wastes (such as crop straw, weeds, leaves, peat, organic domestic waste, kitchen waste, sludge, human and animal excrement, distiller’s grains, bacterial chaff and other wastes) as the main raw materials. Organic fertilizer made from compost. organictle=”PTFE organic compost fabric” align=”” />

Schematic diagram of PTFE organic compost fabric (above)

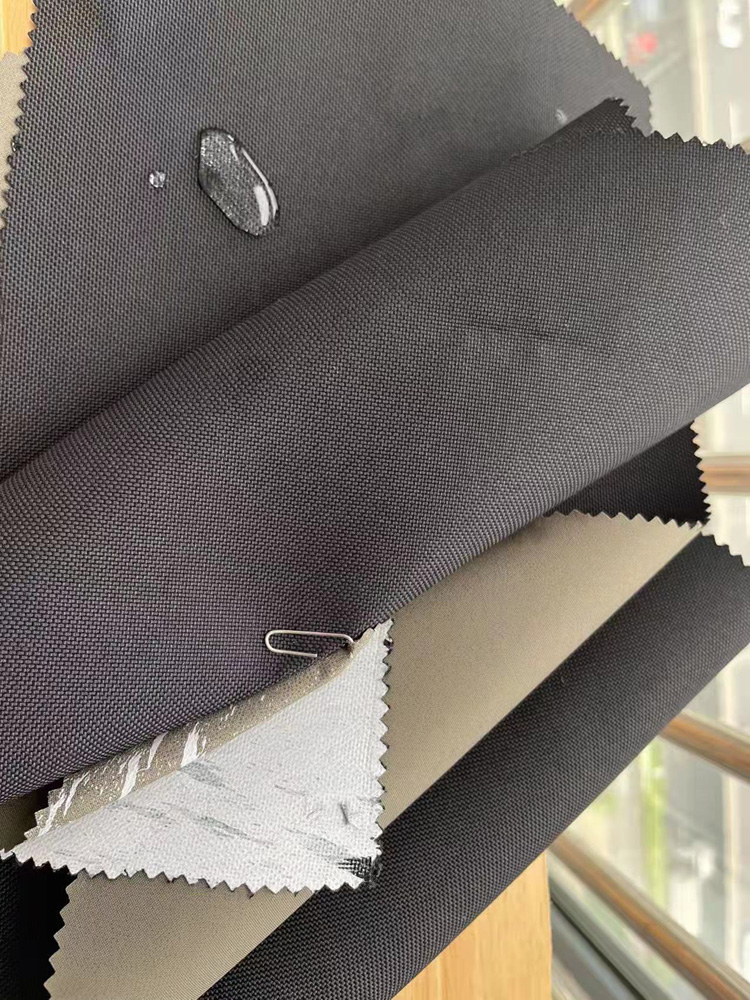

Look at the membrane material characteristics:

e-PTFE (expanded polytetrafluoroethylene) is the core material of fermentation membranes. This material is widely used in cold-proof clothing, jackets and other fields in the market. Due to the increasing demand in the aerobic fermentation membrane market in recent years, some manufacturers have directly applied membrane materials originally used in the clothing field to the aerobic fermentation membrane industry, and the working conditions of the two are very different. .

A good membrane material must have the following characteristics:

Breathable: it can cooperate with the air supply system to provide suitable oxygen concentration for thermophilic aerobic microorganisms.

Moisture permeable: Fermented materials usually have high moisture content, and moisture permeability can help remove water quickly and reduce the moisture content of the material.

Effectively block odor: Odor is an important indicator of whether environmental protection standards are met. The membrane can effectively block odor and is almost invisible at the fermentation site.

It has thermal insulation properties: the membrane can still ferment normally in the extremely cold weather of -30℃ in the cold northern region, and can produce fertilizer on time throughout the year.

Oil and water repellent, long-term non-blocking: Prevent stains from adhering for a long time and causing the membrane to block the pores, affecting its moisture and air permeability, thereby affecting its service life.

Service life: It can be recycled indoors and outdoors, is not affected by rain or snow, and has a long service life, which can reduce operating costs for farmers.

ePTFE organic composting membrane, with ePTFE microporous membrane as the core technology, can create an effective outdoor composting system at a fraction of the cost of the original roof system.

The compost film covering fabric system can prevent the moisture of the finished product while ensuring that the moisture that needs to be retained is not lost, allowing the decomposition of materials to proceed smoothly, which is very important especially in arid areas. Its unique molecular filtration microporous structure means that it is almost impossible to Let bacteria and odors pass through.

The ePTFE organic compost fabric prevents the leakage of odor, dust, and bacteria, ensuring the health and safety of residents in the surrounding areas of the project and project operation and maintenance personnel. It prevents damage to the pile and interrupts the composting cycle under severe weather conditions, and promotes faster and more uniform aerobic decomposition. .

The ePTFE organic compost fabric is lightweight, breathable, can be exposed outdoors, is acid and alkali resistant, reduces the time required for composting, and saves operating space, energy and costs.

Fabric business technical support: Ms. Yang 139 1265 2341

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA